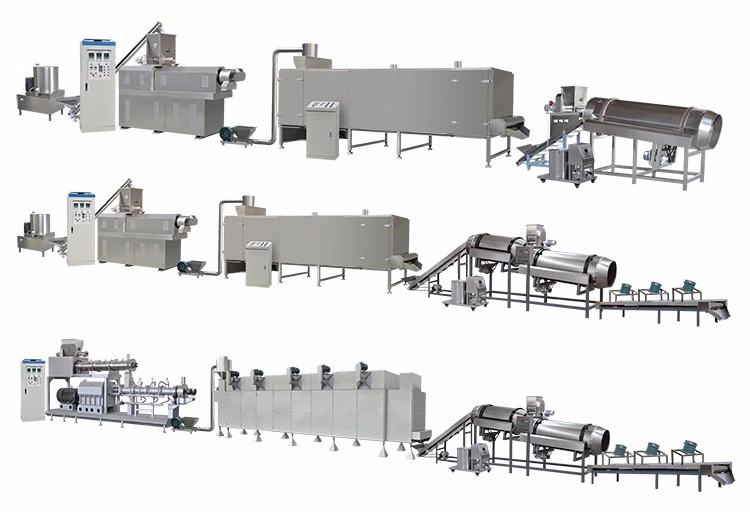

2019 Full Automatic Corn Puff Snacks Food Machine Maize Extruder Puffed Rice Making Machine Puffing Cereals Processing Line

Description

Basic Info

| Model NO. | TSE65/70/85 |

| Material | Stainless Steel |

| Clearning | Self Clearning |

| Raw Material | Corn Powder/Rice Powder/Wheat Flour |

| Processing | Extrusion |

| Screw | 2 Pieces |

| Screw Mateiral | 38 Crmoal |

| Barrel Material | 45#Steel |

| Controling System | Electric Box |

| Voltage | as Customer Requirement |

| Extruder Power | 22kw/30kw/45kw/75kw |

| Machine Name 1 | Puffed Corn Snack Food Making Machine |

| Machine Name 2 | Extruded Snack Food Machinery |

| Machine Name 3 | High Capacity Snack Food Processing Line |

| Keywords 1 | Snack Machine |

| Keywords 2 | Snack Food Extruder |

| Transport Package | Wooden Box |

| Specification | 20m*3m*2.5m |

| Trademark | Shengrun |

| Origin | China |

| HS Code | 8438800000 |

| Production Capacity | 20 Set/ Month |

Product Description

Food Processing Machineries/Snack cake production Machinery/industrial bakery machine:

(1).the food processing line adopts wheat powder and corn flour, or their mixture as main materials, to produce

a variety of twice extrusion ones in different shapes, which are popular inthe market, such as crisp pea, shell, screw, square tube, round tube, sticks,ball and wave.

(2).This line is characterized by unique technique, rational configuration, high automation and stable performance. It can finish steaming, extrusion and shaping in one step without boiler.

The products which can produced from the snack food processing line:

Raw material for snack food:

Corn powder,

wheat flour,

rice powder andother grain powder, we can provide basal formulation as your requirement.

The Parameter of the snack food processing line:

| Model | Installed power | Real power: | Output(KG/H) | Dimension(mm) |

| TSE65 | 45KW | 22KW | 100-150kg/h | 2600*900*1900 |

| TSE70 | 54KW | 45KW | 200-250kg/h | 2600*900*1900 |

| TSE85 | 94KW | 75KW | 350-500kg/h | 3900*900*1900 |

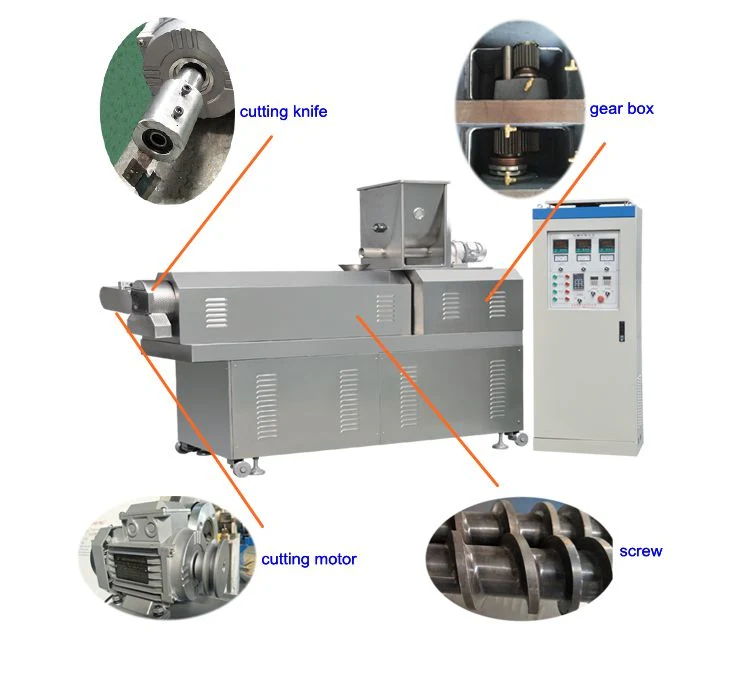

Extruder details:

High temperature and high pressure to realize materials' gelatinization and sterillization;

High stability and high capacity;

Energy saving;

Automatic temperature controll system with visual temperature appearance function;

Automatic water cooling system;

Flexiable screw structure combinations;

Forced gearbox lubrication system;

All motors(engines) with frequency conveters speed control system;

High intensity nitriding treatment of screw barrel;

38#CrMoAl material extrusion screws with long lifetime;

Famous brand engines(motors);

Famous brand frequency converters;

Famous brand electronic elements;

Individual and centrallized controlling panel;

High customization flexiability.

Flow chart for the snack food processing line:

Extruder details:

High temperature and high pressure to realize materials' gelatinization and sterillization;

High stability and high capacity;

Energy saving;

Automatic temperature controll system with visual temperature appearance function;

Automatic water cooling system;

Flexiable screw structure combinations;

Forced gearbox lubrication system;

All motors(engines) with frequency conveters speed control system;

High intensity nitriding treatment of screw barrel;

38#CrMoAl material extrusion screws with long lifetime;

Famous brand engines(motors);

Famous brand frequency converters;

Famous brand electronic elements;

Individual and centrallized controlling panel;

High customization flexiability.

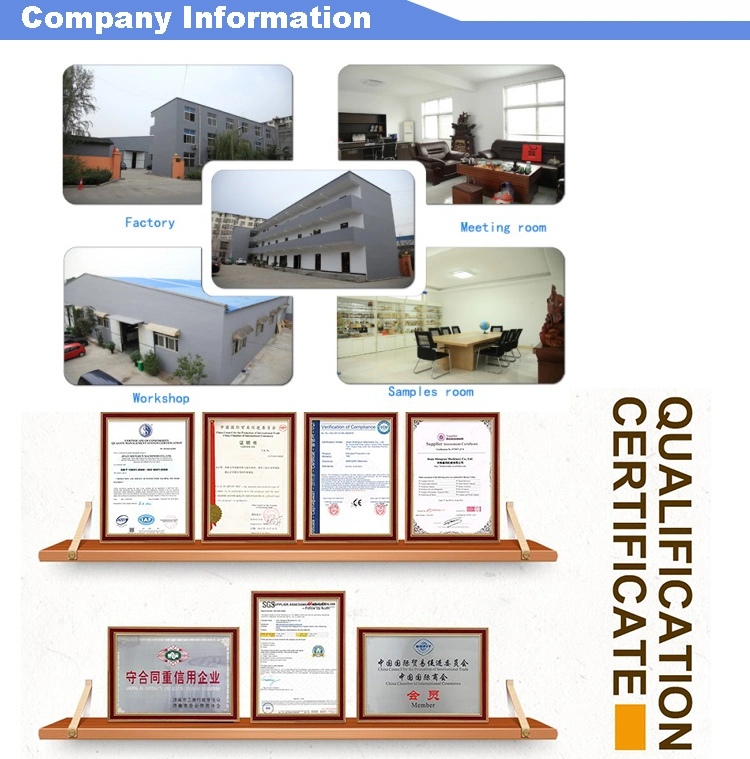

Certification of the machine:

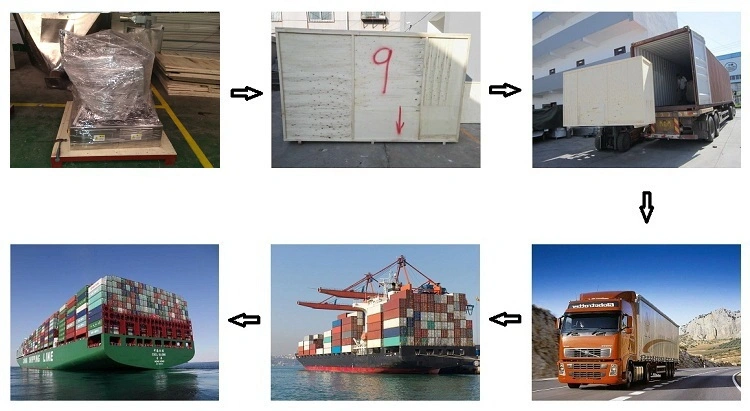

The packaging and shipping forcorn puff snacks food machine maize extruder puffed rice making machine puffing cereals processing line:

Packing: inside plastic bag, outside wooden case for floating fish feed bulking machine (Based on the customers' need adopt the wooden case or wooden pellets, etc.)

Transportation: shipping, train, express or what the client need.

After service:

Before sale services:

1.Provide the free consultation of the equipment

2.Provide the standard device and the flow chart

3. According to the clients' special requirement, offering the reasonable plan and free design helping to select the equipment.

After sale services:

1.Oversea install and debug the equipment.

2.Train the first-line operator.

3.Provide the basic formula

Our Contact