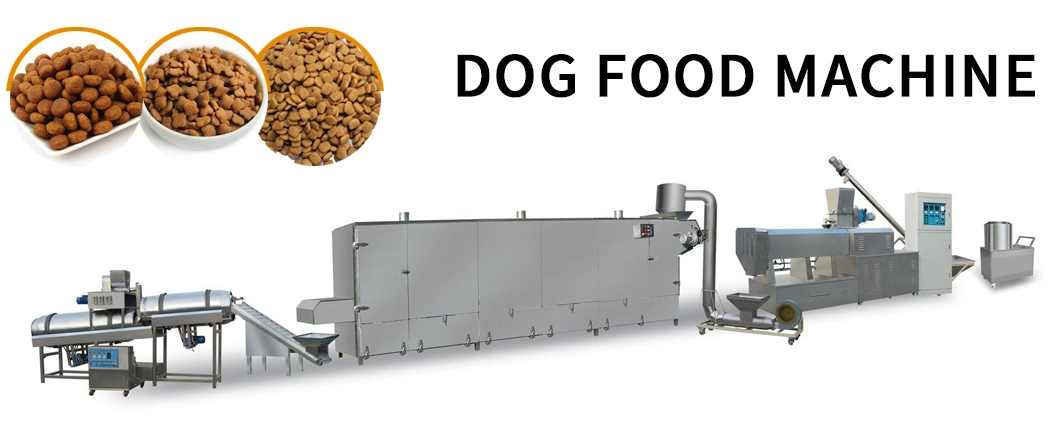

Dry Dog Food Making Extrusion Production Puffed Extruded Pet Pellet Extruder Processing Line

Description

Basic Info

| Model NO. | DSE65/70/75/85/90/95 |

| After-sales Service | Engineers Available to Service Machinery Overseas |

| Warranty | 1year |

| Power Source | Electric |

| Process | Thermal Processing |

| Automatic Grade | Automatic |

| Application | Dog, Fish, Cat |

| Feed Type | Grain |

| Customized | Customized |

| Key Words | 600kg Dog Food Processing |

| Certification | CE ISO9001 |

| Screw Material | 38CrMoAl/12crmov/6542 |

| Materials | 201/304 |

| Output | 100-5000kg/Hour |

| After Sales Service | Custmer Factory on-Site Service |

| Electric Parts | Delta |

| Motor Brand | Siemens |

| Voltage | 380V/220V/440V |

| Condition | New |

| Final Product | Dog Food /Cat Food |

| Motor Power | 22kw/30kw/55kw/75kw |

| Inverter | Delta/Siemens |

| Advantage | Easy to Control |

| Dlivery Time | 30-40days |

| Transport Package | Woodcase and Film |

| Specification | 5-500 cbm |

| Trademark | Dingrun |

| Origin | China |

| HS Code | 8438800000 |

| Production Capacity | 1000set Per Year |

Packaging & Delivery

Package size per unit product 20.00cm * 20.00cm * 20.00cm Gross weight per unit product 20.000kgProduct Description

Dry Dog Food Making Extrusion Production Puffed Extruded Pet Pellet Extruder processing Line

Product Description

It can meet with other needs of modern market by many superior characteristics, such as scientific nutrition formular and easy assimilation. And this line can also make the pet food cored filling, it will be more popular with modern pets.

Product sample

It can also add high fat and protein raw materials, For example, fresh fish, bone, high protein content and high fat raw materials, etc.

3. Products: Different shapes are made by adjusting the dies from extruder.

4. Capacity: See below form.

Model | Installed Power | Power Consumption | Output | Size |

DSE - 65 | 74 kw | 52 kw | 140-160 kg/hr | 17x1.3x2.2(m) |

| DSE - 70/75 | 105 kw | 75 kw | 240-260 kg/hr250-350 kg/hr | 20x1.5x2.2(m) |

| DSE - 85 | 205kw | 150 kw | 500-600kg/hr | 30x1.5x2.6(m) |

| DSE - 90 | 132kw | 75kw | 800-1200kg/hr | 35x2.5x3.8(m) |

| DSE - 95 | 165kw | 90kw | 1500-2000kg/hr | 40x3.5x4.5(m) |

| DSE - 130 | 280kw | 132kw | 3000-3500kg/hr | 45x4.5x6.0(m) |

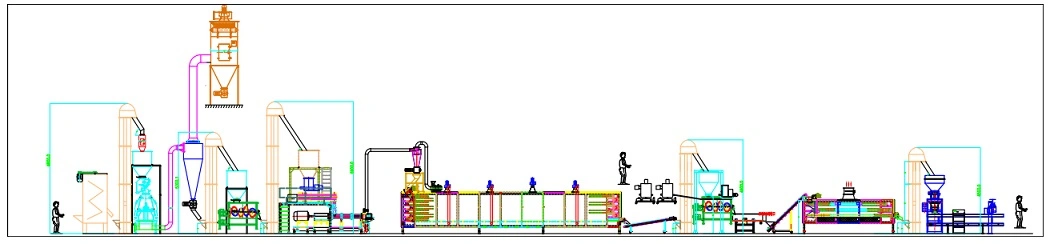

5. Flow chart: Milling machine→Mixer→Screw conveyor→Extruder→Air conveyor→Dryer→Flavoring machine→Hoister→Cooling machine→Packing machine

7. Machines Materials: All the pet food extruder machine are made by stainless steel, this line is with reasonable design and with high automation; The screws are made by alloy steel, with building block system structure and self-cleaning function.

High configuration extruder machine with water cooling system and wear resistant bushings and combined screw can keep extruder working for a long time. PLC control easy to operate.

Company information

Jinan Dingrun Machinery Company is a special extrusion machinery manufacturer. Factory covering 6000m3.Have 100 workers and 15 engineers.We have 15 years experiences.With our many years' research and study, extrusion techniques have been widely used in many fields. Our products consist of single/double-screw extrusion snacks machinery, breakfast cereal and corn flakes machinery, fish feed machine, pet food machinery, dog chew machinery, fried food machinery, etc. We can supply individual items of equipment or complete factory layouts and lines, which are custom-built to suit the requirements of customers.

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shipment after inspection

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Q: How about the machine warranty?

A: We provide 1 year warranty, Lifetime service

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers' need.

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Next: Multifunctional Dry Pet Dog Cat Food Sinking Fish Brid Feed Pellet Extruder Making Processing Line

Our Contact