Pet Food Machine Dog and Cat Daily Food Processing Line

Description

Basic Info

| Model NO. | DSE65/70/75/85/95/115 |

| Feed Type | Grain |

| Customized | Customized |

| Key Word 1 | Dog Food Production Line |

| Key Word 2 | Pet Food Extruder Machine |

| Model | Dse65/70/75/85/95/130 |

| Certification | CE ISO9001 |

| Screw Material | 38CrMoAl/12crmov/6542 |

| Materials | 201/304 |

| Output | 100-5000kg/Hour |

| After Sales Service | Custmer Factory on-Site Service |

| Electric Parts | Delta |

| Motor Brand | Siemens |

| Voltage | 380V/220V/440V |

| Final Product | Dog Food /Cat Food |

| Motor Power | 22kw/30kw/55kw/75kw |

| Inverter | Delta/Siemens |

| Advantage | Easy to Control |

| Transport Package | Woodcase and Film |

| Specification | 5-500 cbm |

| Trademark | Dingrun |

| Origin | China |

| HS Code | 8438800000 |

| Production Capacity | 1000set Per Year |

Product Description

Pet Food Machine Dog and Cat Daily Food Processing Line

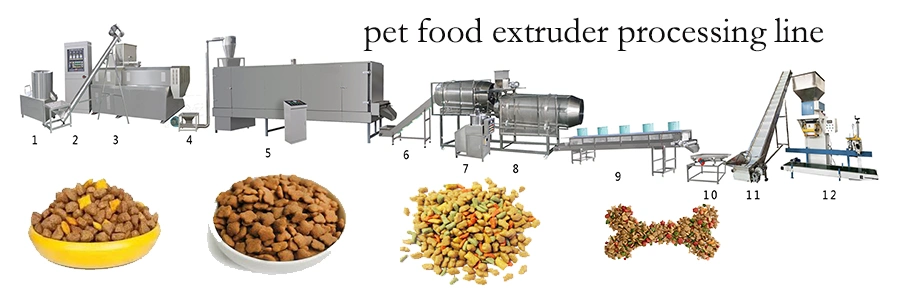

Production line Description

Dog food machine can be used for the production all kinds of dog foods, we will design the moulds to make fifferent shapes according to customers'specific requirement on the shapes of their aimed products.

Flow chart of dog food production line:

Milling Machine→Mixer → Conveyor→ Extruder→ Conveyor→ Dryer→ Conveyor→ Flavoring machine→ Cooling Machine→ lifter Packing Machine

Raw material & final products

Most dog food pellet including animal protein and plant protein, Plant protein adopts corn flour,rice flour,wheat flour,soybean flour,peanut cake powder…..Animal protein adopts fish meal, chicken meal,crab meal, sleeve-fish meal and so on

Final products sample:

Main machines details

Twin Screw Extruder model option for customer to choose :

Model | Installed Power | Power Consumption | Output | Size |

DSE - 65 | 74 kw | 52 kw | 140-160 kg/hr | 17x1.3x2.2(m) |

| DSE - 70/75 | 105 kw | 75 kw | 240-260 kg/hr250-350 kg/hr | 20x1.5x2.2(m) |

| DSE - 85 | 205kw | 150 kw | 500-600kg/hr | 30x1.5x2.6(m) |

| DSE - 90 | 132kw | 75kw | 800-1200kg/hr | 35x2.5x3.8(m) |

| DSE - 95 | 165kw | 90kw | 1500-2000kg/hr | 40x3.5x4.5(m) |

| DSE - 130 | 280kw | 132kw | 3000-3500kg/hr | 45x4.5x6.0(m) |

1. High-strength cabinet, good stability2. The screw material is alloy material, twin screw, easy to clean3. Rotary cutting adopts straight cutting, easy to adjust the cutter head4. Siemens main motor, good quality and long service lifeWet type equipment

1. Cantilever rotary cutting, suitable for large output, quick tool setting, and more convenient adjustment2. Reinforced high-torque new cabinet, with water cooling and filter, cabinet material QT400, aging treatment, good stability3. The barrel is made of No. 45 steel with wear-resistant bushings, which has a long service life and low replacement cost4. The modulator can increase the protein content, increase the output of the same model, and the blades can be adjusted for easy cleaning

Our company

Jinan Dingrun &Bright Machinery Company is a special extrusion machinery manufacturer. Factory covering 6000 square meter.Have 100 workers and 15 engineers.We have 15 years experiences.With our many years' research and study, extrusion techniques have been widely used in many fields.

customer and project

Certifications

Our service And FAQ

Service

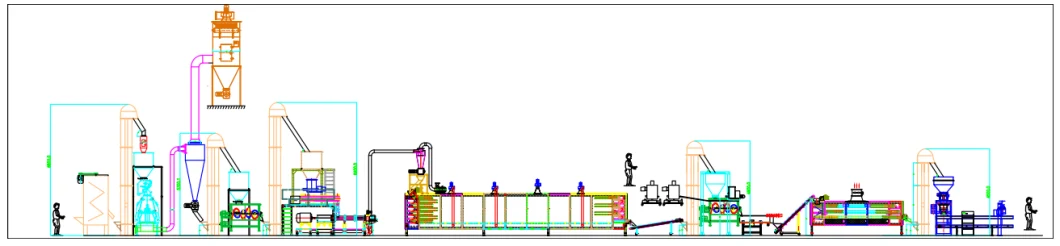

1)Provide factory layout according to your factory size in advance;2)Provide the basic formula;3)Inspect the machine before leaving the factory; Oversea installation and commissioning equipment;4)Technician will work with your workers together and teach your workers how to install machines, how to operate machines, how to maintain machines during daily working;5)Our engineers will teach your workers how to clean the extruder, how to change the screw, how to change barrel etc, and provide technology support with you forever;6)Provide English Version of Installation / Operation / Service / Maintenance Manual.

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shipment after inspection

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators

Q:Do you supply any formula to buyer?

A: yes, we supply formulas to buyer

Q: What's the warranty?

A: warranty one year.

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers' need).

• We can supply fumigation package and certificate. • Shipping, train, express or upon clients' demands.

Prev: Plg Disc Continuous Dryer for Chemical Fertilizer, Pigment, Dyestuff

Next: Continuous Vibrating Fluidized Bed Dryer for for Screw Extrusion Particles and Swing Granules

Our Contact