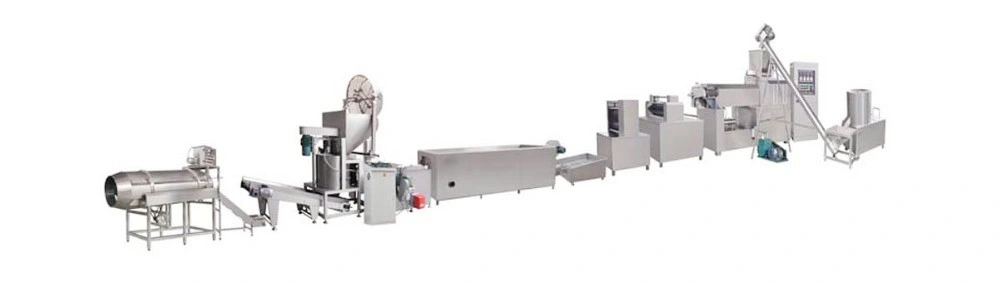

The Newest 80-120kg/H Flour Snack Food Fried Pasta Processing Line

Description

Basic Info

| Model NO. | IMF-Fried Pasta Processing Line |

| After-sales Service | Online Support |

| Warranty | 1 Year |

| Certification | CE, Fried Pasta Processing Line |

| Power Source | Electric |

| Process | Fried Pasta Processing Line |

| Automatic Grade | Automatic |

| Application | Fried Pasta Processing Line |

| Customized | Customized |

| Product Name | Fried Pasta Processing Line |

| Capacity | 80-120kg/H 100-150kg/H 250-350kg/H |

| Final Shape | Triangle,Bone,Fish,Round,Fish,Granule etc |

| Contact | Iris |

| Weight | 8000 Kg |

| Function | Soya Grinding |

| Dimension | 18000*1200*2000mm |

| State | New |

| Voltage | 380 V 50 Hz Three Phase, 220V/380V |

| Usage | Fried Pasta Processing Line |

| After Warranty Service | Online Support |

| Marketing Type | New Product 2021 |

| Applicable Industries | Food & Beverage Factory |

| Machinery Test Report | Provided |

| After-Sales Service Provided | Video Technical Support, Online Support |

| Transport Package | 1 Set Per Bag. or Customized Packaging. |

| Specification | 18000*1200*2000mm |

| Trademark | IMF |

| Origin | China |

| Production Capacity | 80-120kg/H 100-150kg/H 250-350kg/H |

Product Description

| Product Name | High quality DG75-II Capacity 250-350kg/h snack Fried Pasta Processing Line |

| Certification | ISO2001 |

| Main motor | siemens |

| Energy | electric or gas |

| Material | grist |

| Dimension(L*W*H) | 44200*5600*3000 |

| keywords | Fried Pasta Processing Line,Fried Food Processing Line,Snack Food Fried Pasta Processing Line |

Basic Information of Fried Pasta Processing Line* The production line uses wheat flour,corn flour,corn starch,tapioca starch ,potato starch as raw material .* By cooking ,cutting etc process to produce spiral,tube,onion ring,waved chips etc 2D snack pellet.Also can equip with pattern pressing machine and compound machine to produce burgles ,net crispy,pani puri etc 3D snack pellet.* By drying,frying and flavoring ,the snack pellet can be made to be crispy ,vivid instant-eat twice extrusion puffedfood.Combinations of unit screw and precise control of processing ,that achieve higher quality and various products with more chosen for raw material.For 2D Snacks Pellet:Raw material mixer--- Twin screw extruder/single screw extruder --- cooler--- feeding cutter --- rotating dryer --- automatic fryer---automatic flavoring machineFor 3D Snacks Pellet:Raw material mixer--- Twin screw extruder/single screw extruder --- Patterning --- Shaping -- Separating --- Sieving --- Low temperature drying -- frying -- deoiling -- flavoring

Process flow of production

Equipment flow: mixer →single-screw extruder → shaping machine → cooling machine → baking machine→ flavoring line

Application of Fried Pasta Processing Line

This Double-screw fried wheat flour snack processing line uses double screw extruding technique to replace the traditional steam booling process with high efficiency and no pollution without a boiler. The raw material can be total whear flour, or mixing with corn powder, rice powder, or others. By changing the moulds, the products can be in different shapes. After fried and flavored,the final snacks will be crispy and tasty. This line has features of continuous working, stable performance, and reasonable design.

Xi'an International Mechanical Factory, was established in May 2010. It is a professional supplier of Packaging Machine, Chemical Machinery, Pharmaceutical Machinery, Food & Beverage Machinery, Feed Processing Machine. It has absolute advantage because of strong research strength, modern management system and high-quality marketing team. Now we have 3 GMP standard workshop, Meanwhile, the factory is equipped with the researching and quality inspection centre, with strong technology research and development strength. We also have 3 salesdepartments over 30 people and sell our products all over the world. For customer's needs, OEM service is also acceptable. If you have a good idea in new product production but lack of laboratory device and human resource, we are glad to solve this problem for you. Sincerely hope to strengthen exchanges and cooperation with friends from both home and abroad.

Q: Where is your factory ? How can I visit your factory ?

A: Our factory is located In Xi'an , Shaanxi . We are warmly welcome you visit our Factory if you have a travel plan

Q: How can I know your machine is designed for my product ?

A: If you don't mind, you can send u sample and we test it on the machine. During that time, we will take video and clearer picture for you. If chance, we can take video online and show u

Q: How can I trust you for the first time business ?

A: Please check our business license and certificate. And if you don't trust us, then we can use Alibaba Trade Assurance service. it will protect your money during the whole stage of the transaction

Q: How about the after service and guarantee period ?

A: We make the guarantee time 12 months from the machine's arrival in buyer's facility and we have a professional team with an experienced technician to serve abroad and do the best after service to assure the machine whole life usage

Q: How do we contact you ?

A: Please leave a message and click "send" to send us an inquiry.

Our Contact