Recirculating Batch Dryer

1.4/6/8/12 grooves and mixed flow to make sure the drying evenly, ultra drying area and multi layer could improve drying

Description

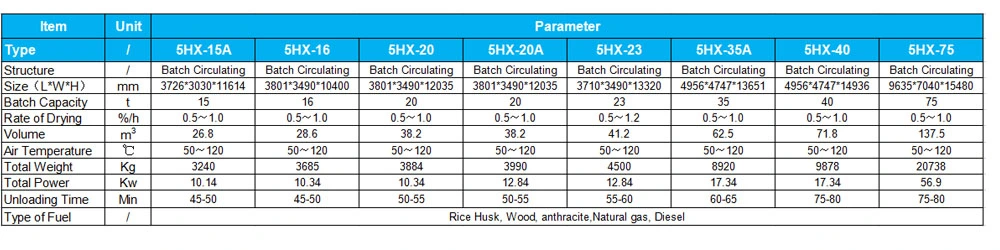

Basic Info

| Customized | Customized |

| Air Temperature | Low Temperature |

| Drying Type | Batch Circulating |

| Type of Air Flow | Transverse |

| Heat Source | Biomass, Rice Husk, Diesel, Gas |

| Transport Package | Wooden Box |

| Trademark | Jinxi |

| Origin | Anhui China |

| HS Code | 8419399090 |

| Production Capacity | 5000 Sets/Year |

Product Description

Anhui Jinxi Machinery Technology is located in Hefei High-Tech Zone. capital of East China's Anhui province. It has very convenient transportation. The land occupies an area of more than 18,000 square meters with 290 employees. We have our own brand and accept customized OEM. And we hope you can also become our local distributor.

Our company is a high-tech enterprise engaged in research, development, design and manufacturing of batch circulating grain/seed /vegetables/herb dryer and biomass stove equipment more than 20 years. Professionally provide complete sets of grain drying system solutions to meet different grain drying needs in different regions. It is widely used in the drying of paddy, wheat, maize,bean and other grains and their seeds, which can ensure the drying quality of grains and the germination rate of seeds, which not only improves the commodity value of grains, but also ensures the drying quality and speed is improved, and it is very popular among users. Our company have obtained more than 30 national invention patents.

Our company insists on developing the market with quality, and the product quality is continuously improved, and has obtained ISO9001 quality management system, ISO14001 environmental management system, OHSAS18001 occupational health and safety management system certification.

Our company has a strong R&D team working and possesses rich practical experience and strong research and development capability. Cooperate with Anhui Agricultural University and Hefei University of Technology to establish an internship base and an industry-university-research base. In 2016, it was awarded national high- tech enterprise.

Best lead time, Best quality, Best warranty, Best service is our constant pursuit!

1.Why choose us?

We are leading manufacturer of grain and vegetable dryer more than 20 years in China. We have our own R&D and many invention patents.

We have professional expert for machinery and software to fulfill any requirements what you want and accept customized OEM and ODM.

We have professional engineer to service after sale.

2.Why do we need a grain dryer?

With a grain dryer, you can dry your grains when they are still fresh and prevent grain mold. Your harvest will no longer be at the mercy of the weather. Also, the paddy dried at low temperature is alive and suitable to make high value small-package rice, increasing your income.

3.How to choose the right dryer model?

This depends on your grain type, kernel sizes, shapes and quantity. We have various models available. Please check our website for the list of products that can be dried.

4.Could a dryer be installed outdoors?

Grains can also get wet during loading and unloading.Rain water invades the dryer, rust and reduced lifespan.

5.Could a single re-circulating type grain dryer dry various grains?

You can maximize your return of investment by using the same dryer to dry various grains and seeds.

6.I am not sure if my product can be dried by your dryers.

We have more than 20 years of experience in drying. If you aren't sure, please provide detailed information of your product, We can make assessment for you.

7.How to choose the right heat source for a grain dryer?To minimize drying cost, biomass fuels such as rice husk, corn cob, wood pieces, coconut shell and coffee hulls can be our dryers' heat source.

8.How long is your warranty?

Within one year after installation and commissioning. Within 24 hours reply technology questions by video or email.

9.How about the payment terms you can accept?

We can accept the T/T and irrecoverable L/C at sight.

10.How long the leading time?

According to your quantity. Generally within 10-15 days after received your deposit.

Prev: Pharmaceutical Food Industry Electric Batch Cabinet Tray Dryer

Next: Batch Type Circulating Agriculture Machine Wheat Maize Corn Paddy Rice Grain Dryers for Sale

Our Contact

Send now