Niknak Kurkure Machine Puffs Machine Snack Processing Line

Description

Basic Info

| Model NO. | EXT |

| Product Name | Single Screw Extruder Nik Naks Corn Snacks Kurkure |

| Machine Sheeting Material | Stainless Steel |

| Capacity | 100kg/H--300kg/H |

| Operation | Automation |

| Color | Silver |

| Food Shape | Squeezed Twisted |

| Food Raw Matrial | Corn Grit |

| Electric Parts | Siemens,LG,ABB Ect |

| Production Type | Frying/Roasting Type |

| Food Capacity | 100-200kg/H |

| Transport Package | Wooden Cases |

| Specification | 18000*1400*2200 |

| Trademark | Shengrun |

| Origin | China(Mainland) |

| HS Code | 8438800000 |

| Production Capacity | 30 Sets/Month |

Product Description

Brief IntroductionKurkure/Cheetos are special extruded snacks with crunchy and great taste.They are made by a special extrusion processing.The corn grits are moisturized in the flour mixer with water and fed to the Rotary Head Extruder.By adjusting the raw materials, temperature and pressure etc.Due to the two rotary plates,corn grits are squeezed and twisted to curls shapes.The cutting knifes can cut into required lengths.The Kurkure/Cheetos can be fried in cooking oil or toasted in oven and then cooled before flavoring.Seasoning is sprayed on the surface to achieve different favorable taste.

Production Process:

Mixer---Screw conveyor---Kurkure machine---Hoister---Separating screen---Vibrating feeder--- Continuous fryer---Vibrating deoiling machine---Flavoring line

Mixer---Screw conveyor---Kurkure machine---Dryer---Flavoring Line

- Rotating Speed: Adjustable

- Temperature: Adjustable

- Pasteurization function with high temperature and high pressure

- Flexible collocation of equipment

Model:EXT76

Output:100-150kg/h

Size:1800x1300x2200(mm)

Motor power:22kw

Real power: 22kw

Installed power: 28kw

Function:Extruded the material,make it become the kurkure food.

Kurkure Machine Reference Parameter

| Model | Frying Type | Roasting Type |

| Installed Power(kw) | 85 | 80 |

| Power Consumption(kw) | 65 | 65 |

| Production Capacity(kg/h) | 100-200 | 100-200 |

| Dimension(mm) | 21000*1800*2100 | 18000*1400*2200 |

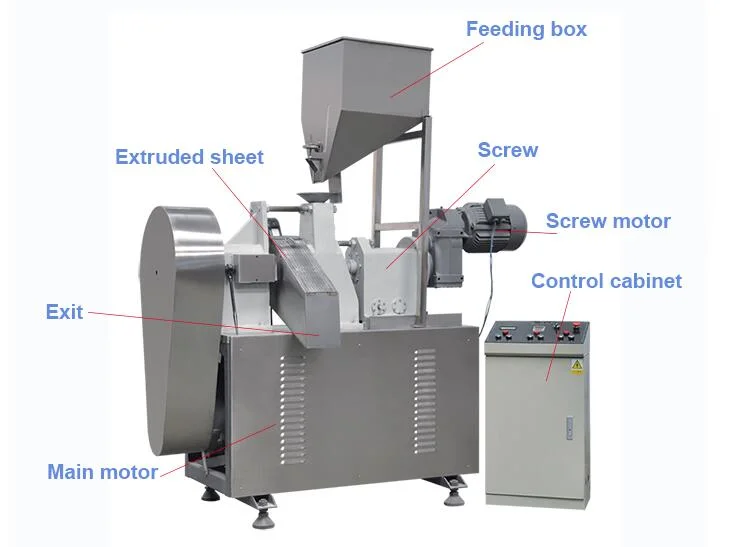

Machine Function

| Machine Name | Function |

| Mixer | Mix the material,make full mix |

| Screw conveyor | Conveying the material into the extruder |

| Kurkure machine | Extruded the material,make it become the kurkure food. |

| Hoister | Conveying the kurkure food. |

| Separating screen | Clean up debris. |

| Vibrating feeder | Scattered the product |

| Continuous fryer | Fryed the product |

| Vibrating deoiling machine | Vibrating deoil from kurkure food. |

| Flavoring line | Mix the seasoning with products |

Sample

Our Service

Pre-sale service:

24 hours online service .

Configure the machines as your output or request.

In sale service:

Strictly supervise the manufacture of the machines

Convey the manufacture information to you in time.

After sale service:

1 year warranty for the machines.

Overseas installation and train the first-line operators.

For any questions, professional technicians will solve for you timely.

FAQ

1. Is configuration(allocation) fixed standard?

Answer: No, it is flexible, we will equip machines based on your requirement.

2. Can I come to check your company?

Answer: Welcome to visit us! We will show our machines in our factory.

3. Do you have shipping agent for delivery?

Answer: Yes, we have reliable shipping agent. They can offer a good freight and take care the process very well.

4. Can you test our formulation with your extruder?

Answer: As long as you trust on us, we can test your basic formula, then you can see the outcome and place order without any hesitation.

5. Why the price in the web is a range?

Answer: As we have many models, and the production lines' configuration are various. So we will equip machines based on customers' specific requirement. So, the price range is for reference.

Introduction Of Company

Our Company is an industry and trade integrated enterprise. The company is committed to research and develop extrusion machinery and related ancillary equipments. It is covering mainly machinery and equipment for corn meal milling system,corn flakes/breakfast cereal system, baby food system, corn puff snacks system, pellets system, artificial rice system, soy nuggets system; as well as pet food/fishfood system.Our factory was founded in 2009. Our machines have been exported to many countries of Asia,America, Africa, Europe etc. Machines are welcome in the counties. So until now, there are not only direct customers, but also some long termcooperation agents.Dont hesitate to contact us.

Packaging&Shipping

1. Package of inside is plastic film, outside is wooden or plywood cases, which is seaworthy.

2. We can supply fumigation package and certificate.

Exhibition

Certificate

Our Contact