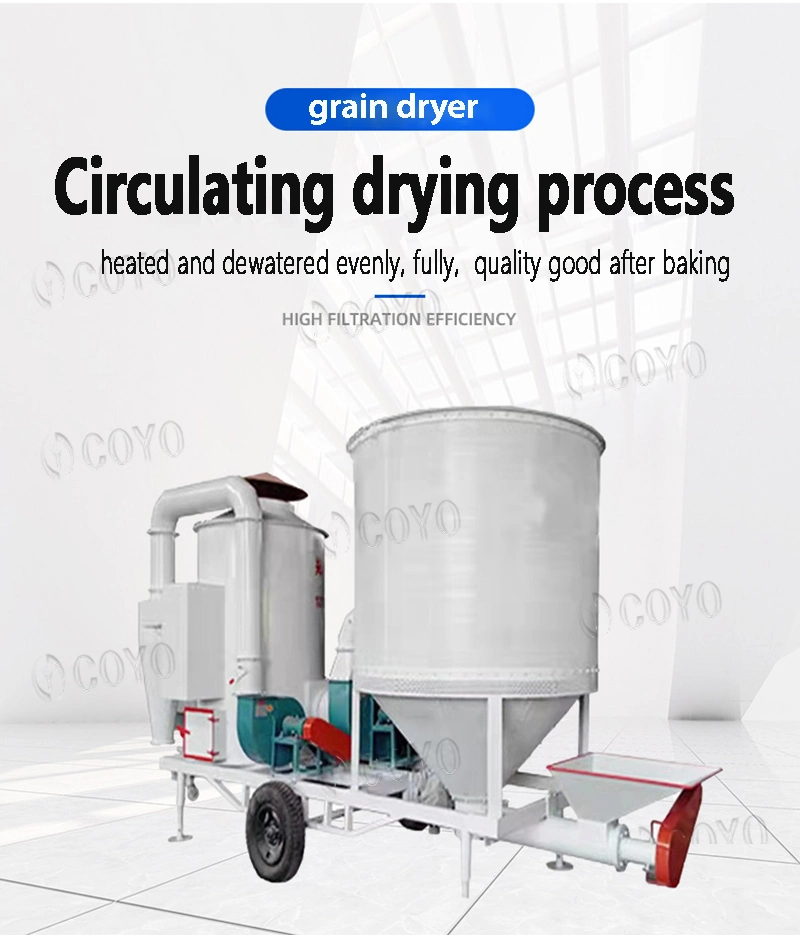

Mini 2 Ton Per Batch Mobile Diesel/Coal/Straw /Natural Gas Fuel of Grain Dryer Machine

Description

Basic Info

| Customized | Customized |

| Fule | Wood/Diesel/Gas/Electricity |

| Transport Package | Export Packaging |

| Trademark | COYO |

| Origin | China |

| Production Capacity | Will Be Adjusted |

Product Description

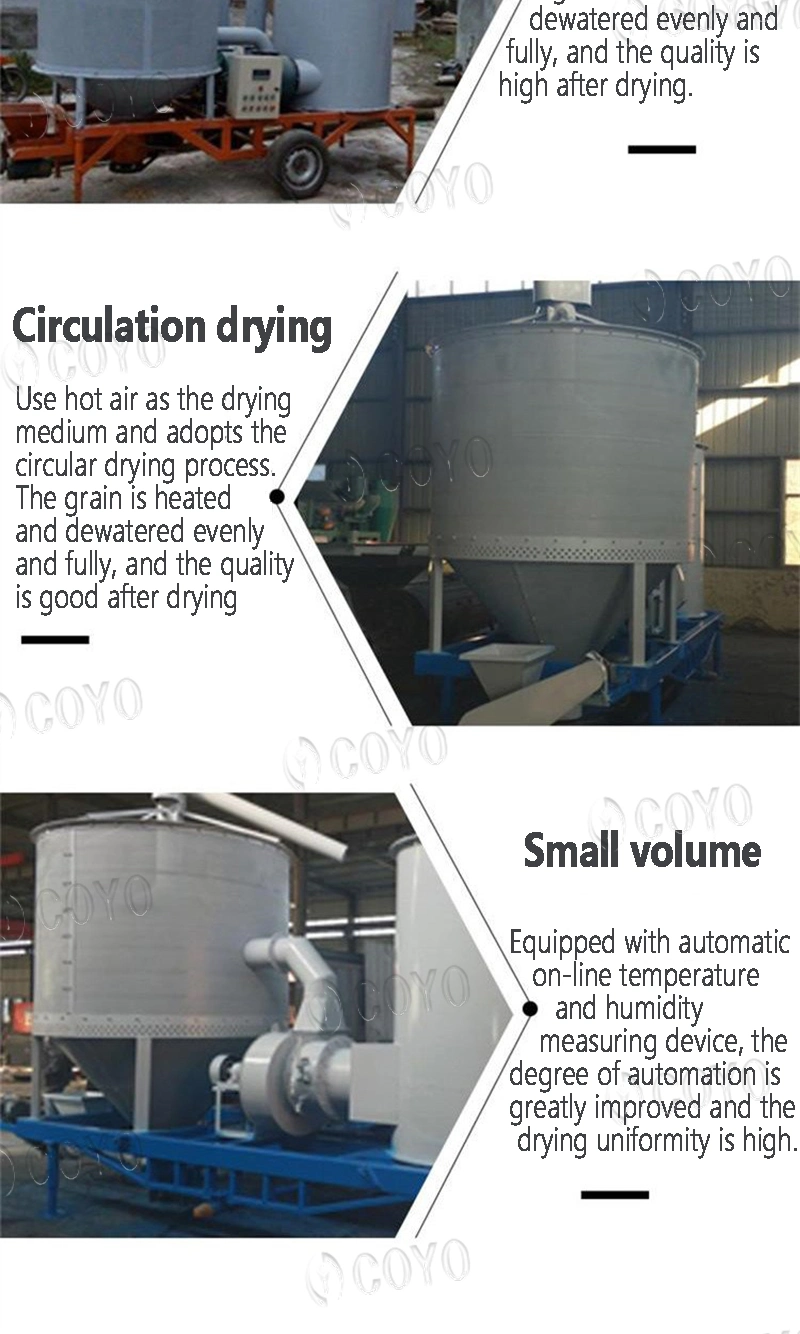

This model adopts mixed flow drying process and is a mixed flow dryer.

The corn dryer (corn drying equipment) uses hot air as the thermal medium to dry grain. The combined drying process of "downstream countercurrent" is adopted, and the "subsection variable temperature drying" is implemented according to the grain heating temperature. A slow drying section is designed between each drying section, and the "drying slow drying" is carried out alternately.

The grain flows from top to bottom, the hot air enters from the inlet angle box, passes through the grain layer from top to bottom, and the waste gas is discharged through the exhaust angle box. Hot air and grain flow flow flow in the same direction and reverse direction, which is called mixed flow. When the hot air passes through the grain layer, it transfers heat and water with the grain: the hot air transfers heat to the grain to raise its temperature, the grain is heated, and the water evaporates into the air and becomes exhaust gas. The dried hot grain flows down to the slow Su section, through which the temperature and moisture in the inner and outer layers of grain tend to balance, so as to achieve uniform precipitation.

The grain enters the cooling section after cooling. After cooling, the grain is cooled to the stored grain temperature, and then discharged from the grain discharge section. The corn dryer (corn drying equipment) uses high hot air temperature in the drying section at the top to quickly heat up the grain and take away part of the surface moisture; The middle drying section adopts medium hot air temperature to remove a large amount of water; After the above drying section, the grain temperature has increased, so the lower temperature in the bottom drying section can remove the water with strong adsorption capacity in the grain and avoid the grain temperature rising too high; After sufficient cooling in the cooling section, the outgoing grain reaching moisture and temperature can be directly stored in the warehouse. The machine optimizes and combines the "downstream" and "countercurrent" drying processes to achieve results.

Feature

1. It is used for classification according to the size of fruit shape.

2. Through the walking of the silicon tape, the fruits fall into the receiving tank at the appropriate aperture and are discharged from the material guide port.

3. Bell mouth grading is adopted to standardize the grading hole spacing.

4. It is made of delicate silica gel, which is in direct contact with fruits, round and smooth without damaging materials.

Technical Parameter

| Model | HG-3 | HG-5 | HG-10 | HG-15 | HG-25 | HG-35 |

| Storage capacity | 3m3 (1bin) | 5m3 (1bin) | 10m3 (2bins) | 15 m3 (3bins) | 25m3 (4bins) | 35m3 (5bins) |

| Bin diameter | 2m | |||||

| Hot air temperature | Paddy 50-60ºC Maize 100-130ºC Wheat 90-110ºC Bean 90-110ºC | |||||

| Power | 9.7KW | 12.2KW | 23KW | 31KW | 37.4KW | 51.5KW |

| Combustion furnace | Rice husk / coal / firewood / oil / gas | |||||

| Ignition mode | Manual | |||||

| Coal consumption | 7~10kg/h | 15-20kg/h | 25-30kg/h | 35-40kg/h | 60-80kg/h | 80-100kg/h |

| Area covered | 12m2 | 15m2 | 30m2 | 70m2 | 100m2 | 200m2 |

| Weight | 2T | 3T | 5T | 7T | 12T | 16T |

| Precipitation amplitude | Paddy 0.8-1.2%/h,Maize 2-3%/h,Wheat 1.5-2.5%/h | |||||

Prev: 2019 Hot Sale Continuous Vacuum Fryer

Next: Batch Type Electric Heating Tray Dryer for Fruit and Vegetable Drying machine

Our Contact