CE Approved Fully Automatic Fried Bugles Pellets Snack Food Processing Equipemnt Machine Production Line

Description

Basic Info

| Model NO. | DSE65/70 |

| After-sales Service | Engineers Available to Service Machinery Overseas |

| Warranty | 1 Year |

| Certification | CE, ISO9001 |

| Power Source | Electric |

| Process | Extrusion |

| Automatic Grade | Automatic |

| Application | Fried Snacks |

| Customized | Customized |

| Key Words | 200kg Doritos Seller |

| Model No. | Dse65/70/85 |

| Screw Material | 38 Crmoal |

| Output | 100-150kg/H |

| After Sales Service | Engineers Available to Service Machinery Overseas |

| Electric Parts | Chinese Brand or Delta |

| Motor Brand | Siemens |

| Raw Materials | Grain Flour |

| Voltage | 380V |

| Motor Power | 22kw/37kw |

| Manufacturer | Dingrun&Bright |

| Stainless Steel Material | 304 |

| Final Product | Fried Snacks |

| Speed Controlling | Inverter |

| Dlivery Time | 30-40days |

| Transport Package | Wooden Packing |

| Specification | Stainless steel |

| Trademark | Dingrun |

| Origin | China |

| HS Code | 8438800000 |

| Production Capacity | 20pieces/Month |

Product Description

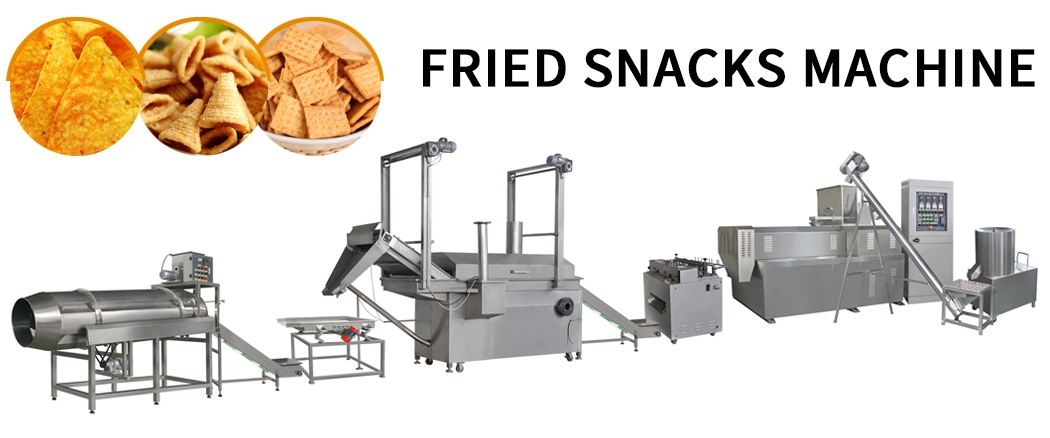

CE Approved Fully Automatic Fried Bugles Pellets Snack Food Processing Equipemnt Machine Production Line

Product description

Product sample

Adopt potato starch, corn starch, cassava starch, wheat flour, corn flour etc. as raw materials.

3. Products: Different shapes are made by adjusting the dies from extruder. 4. Capacity: See below form.

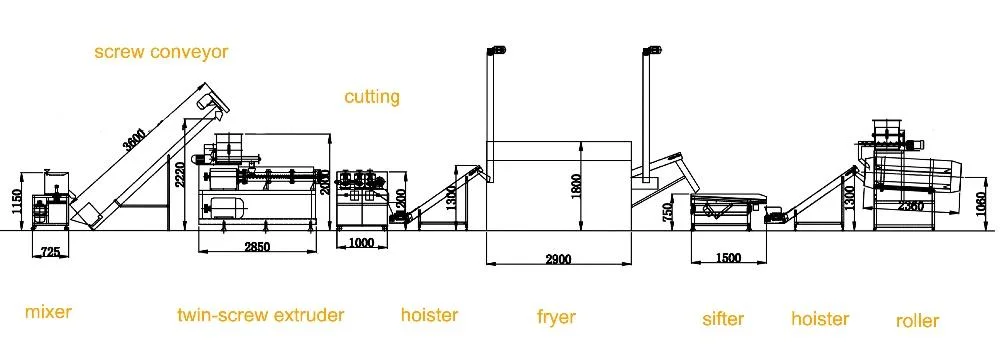

Model | Installed Power | Power Consumption | Output | Size |

DSE - 65 | 119 kw | 75 kw | 100-150 kg/hr | 22x1.3x2.2(m) |

| DSE - 70 | 126 kw | 82 kw | 200-250 kg/hr | 24x1.5x2.2(m) |

5. Flow chart: Mixer→Screw conveyor→Extruder→Hoister→fryer→Sifter→Flavoring machine

High configuration extruder machine with water cooling system and wear resistant bushings and combined screw can keep extruder working for a long time. PLC control easy to operate.

Company information

FAQ

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check the machines.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-35 days if the goods are not in stock, we could discuss before contract

Q: Could you supply all the parameters about the machines?

A: Yes, we will supply all the parameters, price, layout drawing, factory design etc

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shipment after inspection

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators

Q:do you supply any formula to buyer?

A: yes, we supply formulas to buyer.

Q: How about the machine warranty?

A: We provide 1 year warranty, Lifetime service

Packing and delivery

• Inside package is plastic film, outside is wooden or plywood case(based on the customers' need).

• We can supply fumigation package and certificate.

• Shipping, train, express or upon clients' demands.

Our Contact