Batch High Efficiency Large Freeze Dryer Freeze Dryer Industrial

Description

Basic Info

| Heating Method | Electric |

| Material | High Quality SUS304 Stainless Steel |

| Application | Strawberry, Durian, Fig,Red Jujube,Coffee,Meat |

| Applicable Industries | Manufacturing Plant, Food & Beverage Factory, Food |

| Dimension(L*W*H) | Dimension(L*W*H): |

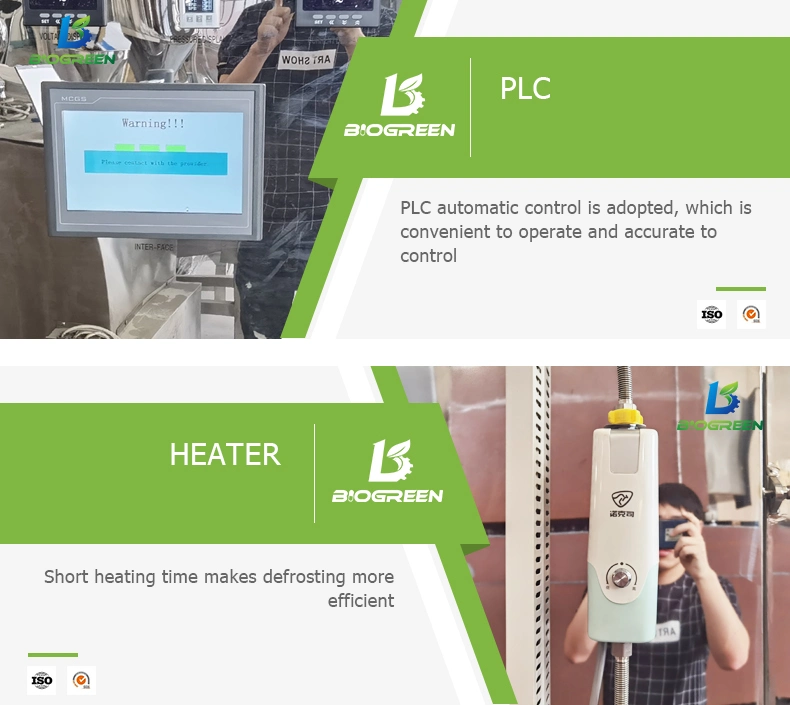

| Key Selling Points | Easy to Operate |

| Core Components | Motor, PLC, Pump, Gear, Engine |

| After Warranty Service | Video Technical Support, Online Support, Spare PAR |

| Installation | Engineer′s Guidance |

| After-Sales Service Provided | Overseas Third-Party Support Available |

| Shelf Areas | Customized |

| Chamber Design Temperature | -70c- +90c |

| Compressed Air | >=40L/Min(P=0.5~0.8MPa) |

| Transport Package | Standard Export Wooden Case |

| Specification | BD-VFD-1-P |

| Trademark | BIOGREEN |

| Origin | Wuxi, Jiangsu |

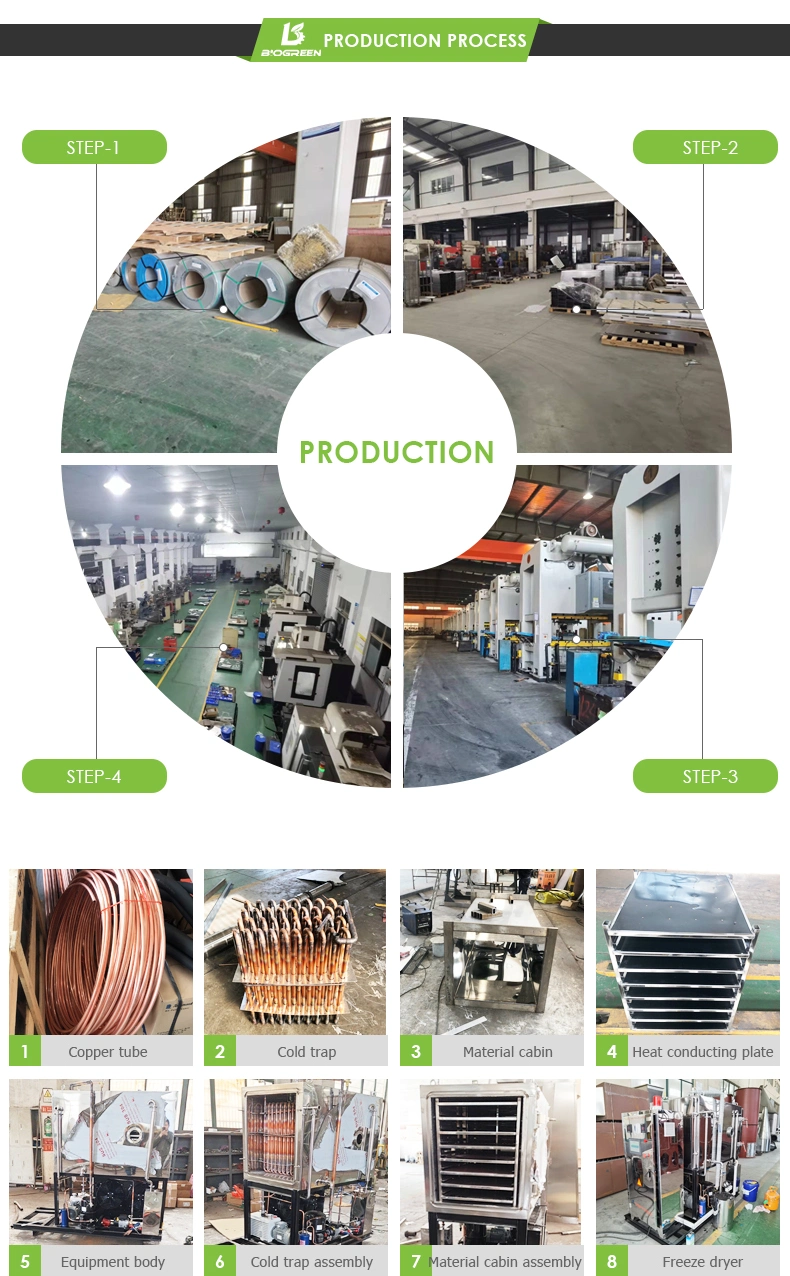

| Production Capacity | 1000PCS/Month |

Product Description

Freeze dryer known as lyophilizer, is the machine to dry different types of material to prolong its preservationtime. There are many kinds of dryers; freeze dryer is the best dryer to make high quality dried products. It is quitedifferent from dehydrator, drying oven, microwave heating, and vacuum heating drying. Drying needs heat, withthose kinds of drying method, heating is in room temperature, so it has harmful to material, and there is hugenutrition and biological activity loss in the drying procedure.

On the contrary, by freeze drying, heating is occurred after the material is completely frozen to -40 C, andmaterial is in frozen status in the whole drying procedure till completely dried. Therefore, the freeze driedproducts preserve its original shape, color and it has no biological activity loss, no nutrition loss. Freeze dryeris suitable for food industry, pharmaceutical industry, chemical industry and laboratory test.

Full range of freeze dryers provided: the small unit is for laboratory and home use; the medium-sized is for foodand pharmaceutical drying application; the large-sized freeze dryer is for food and chemical industry whichrequires mass production by economic equipment with lower energy consumption. We focus on manufacturingfreeze dryer for 10 years with rich installation experience in home and abroad.

Parameter Model | Drying area (m²) | Approx capacity (kg/batch) | Average moisture output(kg/h) | Tray size (mm) | Tray qty (pcs) | Heating pot size (m) | Operation vacuum (pa) | Heating plate temp. (°C) | Power (kw) |

FDG-0.5 | 0.5 | 6 | 0.5 | 310*550*35 | 3 | Φ0.5*1.2 | 133-13 | Normal temp. to +120 | 9 |

FDG-2.0 | 2 | 24 | 2.4 | 540*460*30 | 8 | Φ0.7*2.0 | 13 | ||

FDG-5.0 | 5 | 60 | 6 | 780*540*30 | 12 | Φ0.8*2.7 | 22 | ||

FDG-7.0 | 7 | 84 | 7 | 545*635*35 | 21 | Φ1.1×3.8 | 39 | ||

FDG-10 | 10 | 120 | 12 | 745*635*30 | 21 | Φ1.4*2.1 | 55.8 | ||

FDG-20 | 20 | 240 | 20 | 700*460*30 | 60 | Φ1.8*2.6 | 104.5 | ||

FDG-25 | 25 | 300 | 25 | 680*460*30 | 80 | Φ1.8*4.1 | 122 | ||

FDG-50 | 50 | 600 | 50 | 540*635*30 | 144 | Φ2.4*4.8 | 33+100.5 | ||

FDG-100 | 100 | 1200 | 100 | 288 | Φ2.4*8.9 | 61+176 | |||

FDG-200 | 200 | 2400 | 200 | 576 | Φ2.4*16.6 | 98+340 |

Prev: High Efficiency Speedy Dryer Machine Corn Mobile Dryer Drying Machine Rice Dryer Batch Grain Dryer

Next: Automatic Continuous Conveyor Gas Deep Fryer for Nugget

Our Contact