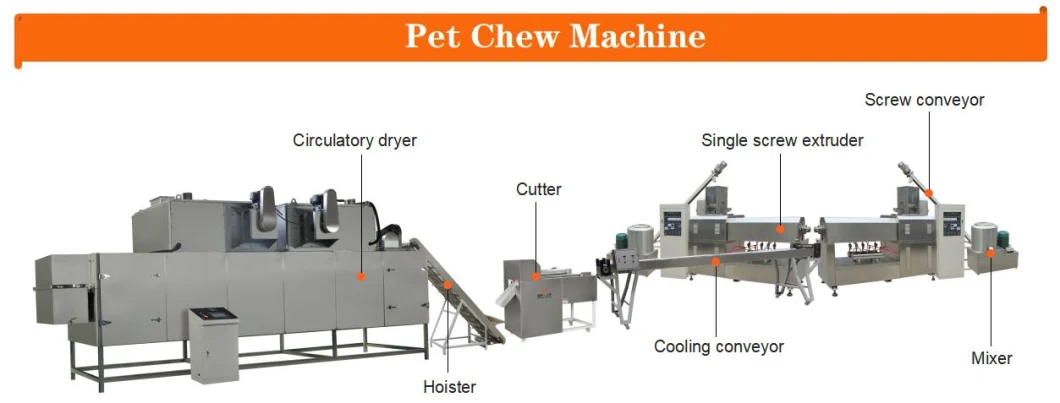

Automatic Pet Dog Treats Dental Chews Snack Food Extruder Processing Machine Production Line

Description

Basic Info

| Model NO. | SR100 single double color 200kg/h |

| After-sales Service | 12 Months |

| Warranty | 12 Months |

| Power Source | Electricity Diesel Steam Gas |

| Process | Machinery Processing |

| Automatic Grade | Automatic |

| Application | Dog, Fish, Cat, Bird |

| Feed Type | Meat and Bone Meal |

| Customized | Customized |

| Energy | Electricity Diesel Steam Gas |

| Certification | CE, ISO9001 |

| Material | 304 Stainless Steel |

| Advantage | Easy Operation High Efficiency |

| Voltage | 380V/50Hz Due to Order |

| Power | 30kw According to Your Requests |

| Type | Feed Pellet Machine |

| Motor | Simens |

| Inverter | Delta |

| Color | Silver |

| Technology | Single Screw Extrusion |

| Raw Material | Grain Flour,Fish Meal,Bone Powder |

| Condition | New |

| Core Components | PLC, Engine, Bearing, Gearbox, Motor, Gear |

| Usage | Commercial, Industrial and Personal Usage |

| Transport Package | Based on The Customers′ Need |

| Trademark | Sunrising |

| Production Capacity | 80-200kg/H, According to Your Requests |

Packaging & Delivery

Package size per unit product 1500.00cm * 400.00cm * 300.00cm Gross weight per unit product 5000.000kgProduct Description

2.Raw material for dog chew making machine:

corn flour, corn powder, bone meal, fish meal.

3.Product Sample

Product Parameters

| Model | Main motor power | Output | Size |

| SR100 Single colour | 30kw | 80-100kg/h | 25000x4500x2500mm |

| SR100 Double colour | 30kw | 100-200kg/h | 25000x4500x2500mm |

Detailed Photos

| Main Accessories | Function |

| Anti-blocking feeder | Makes sure the even feeding and stable discharge of materials. |

| Double shaft preconditioner | Enables the materials stay longer in the preconditioner and evenness in precondtioning, improves the precure degree and increases the capacity. |

| Gearbox | Processed by internationally advanced process technology, ensuring the machines run in long time without malfunction. |

| Lubrication and cooling system | Adopts refined filtration forced cooling, creating best working conditions for the bearings. |

| The feeding system | Adopts double spiral forced feeding, feeding uniformly and widely. |

| The screw | Segmented combined screw, suitable for a wide range of raw materials. With self-cleaning function. |

| The rotary cutting device | Adopts a suspended mold (knife) assembly and a linear bearing tool adjusting device to adjust the tool safely, accurately and quickly. |

Unique structure, high utilization rate of heat energy, high efficiency,environmental protection and energy saving;

Circulation drying process, the moisture difference of the dried product is small, and the drying effect is good. Horizontal overall layout, simple structure, reliable control, convenient and intuitive operation. The frequency motor controls the speed of the mesh belt, and the drying quality can be adjusted flexibly.The food contact part is all stainless steel, corrosion resistant. Energy can be gas heating and steam heating.

| Name | Pet snack cutting machine |

| Output | 120kg/h |

| Power | 1.5kw |

| Size | 1600X800X1300mm |

| Function | The machine USES the servo motor to make the cutting tool realize the instantaneous speed and make the incision. |

Company & Certifications

Jinan Sunrising Machinery Co.,ltd is a professional manufacturer and the model company for advanced and high quality extrusion food machinery in this field. Our company congregates an expert team with ten years experiences in the extrusion machinery industry, not only working hard to constantly researching extrusion technology, but also exploring food processes in order to benefit our clients producing creative food.

After Sales Service

a.) Free consultation service before, during, and after sales;b.) Free project planning and design services;c.) Free debugging of equipment until everything is functional;d.) Free management of equipment long distance shipping from seller's factory to named place by buyer;e.) Free training of equipment maintenance and operating personally;f.) Free new production techniques and formulas;g.) Provide 1 year complete warranty and life-time maintenance service; All spare parts and wearing parts are attached with the machinery for free.

Packaging & Shipping

For dog food extruder machine dry pet food processing machinery* Inside package is plastic film, outside is wooden or plywood case.(the production packaging based on the customers' need)* Only plastic film nude packing with wooden pallet.* We can supply fumigation package and certificate.* Shipping, train, express or upon clients' demands.

FAQ

1.

Q: Are you a trade company or a manufacturer?

A: we are a manufacturer, welcome to visit our factory and check it. 2.

Q: What is your terms of payment ?

A: 30% T/T in advance , 70% balance before shippment after inspection.3.

Q: How about the after-service?

A: We will send 1 engineer to the buyer's factory for 7-14 days period installation and training to the operators.4

Q: If the power supply is not 3ph 380V 50HZ, could you offer the suitable machine?

A: Yes, we can offer the suitable machine according to your power supply, for example 3ph 380V 60HZ, 3ph 415V 60 HZ, 3ph 220V 60HZ and so on.5

Q:Do you supply packing machine?

A: We have long-term cooperation packing machine supplier, we will help to contact them.

Related Products

Our Contact