Automatic Chicken Nuggets Continuous Deep Fryer

Description

Basic Info

| Model NO. | LTF-L LTF-LII LTF-LG LTF-LGII LTF-S |

| After-sales Service | Engineer Service |

| Warranty | 1 Year |

| Type | Fryer |

| Voltage | 380V/50Hz, 220V/50Hz or Required |

| Customized | Customized |

| Product | Automatic Chicken Nuggets Continuous Deep Fryer |

| Automation | Fully Automatic |

| Machine Materials | Food Grade Stainless Steel |

| Package | Standard Export Package |

| Relay | Omron |

| Inveter | Delta |

| Electric Part | FUJI, LG, Omron |

| Certificate | CE, ISO 9001 |

| Transport Package | Strong Fumigation-Free Cases or 20′ Gp or 40′ HQ |

| Specification | LTF-L LTF-LII LTF-LG LTF-LGII LTF-S |

| Trademark | LT |

| Origin | China |

| HS Code | 84388000 |

| Production Capacity | 100set/Year |

Product Description

Automatic Chicken Nuggets Continuous Deep Fryer

Introduction:

Automatic Chicken Nuggets Continuous Deep Fryer consists of automatic belt conveying system, elevating system, oil adding system, oil temperature controlling system, fryer can use electricity, gas, diesel as power source. Fryer can achieve industrial production, has features of easy operation, stable performance and long time working, labor saving, easy maintenance.

1. World-famous Brand Electronic Apparatus ensure the Excellent and Stable Performance.

2. Controller Box made of Stainless Steel or Sprayed-plastic(optional), Allows adjust Frying Time by Variable Conveying Speed as required, Alarm Oil Level.

3. Double Layer 304 Stainless Steel Belt, Preventing Products Floating, Ensure Complete and Perfect Frying Effect.

4. Scrapers fixed on the belt, Make the products come out easily.

5. Electric Belt and Upper Cover Lifting Setting, Make Cleaning more Easier and Save Human Power.

6. Different Heating Methods Optional: Electricity, LPG, Natural Gas, Diesel etc.

| Model | Electric (gas/diesel) consumption | Output | Heating temperature | Dimensions |

| LTF-L | 60kw | 300kg/h | 250°C | 3000x1200x2100mm |

| LTF-LII | 96kw | 400-500kg/h | 250°C | 4000x1300x2200mm |

| LTF-LG | 6-20.5 m³/h(gas) 7-15kg/h(diesel) | 300kg/h | 250°C | 3000x1200x2100mm |

| LTF-LGII | 35m³/h(gas) 8-41kg/h(diesel) | 400-500kg/h | 250°C | 4000x1300x2200mm |

| LTF-S | 45kw | 60-80kg/h | 250°C | 2000x1500x2100mm |

Our Service

A. ) Consultation 24-hour online service before, during, and after sales;

B. ) Project planning and design service;

C. ) Debugging of equipment until everything is functional;

D. ) Management of equipments' long distance shipping from seller's factory to the named place by buyer;

E. ) Training of equipment maintenance and operating personally;

D. ) New production techniques and formulas;

E. ) Provide 1 year complete warranty and life-time maintenance service.

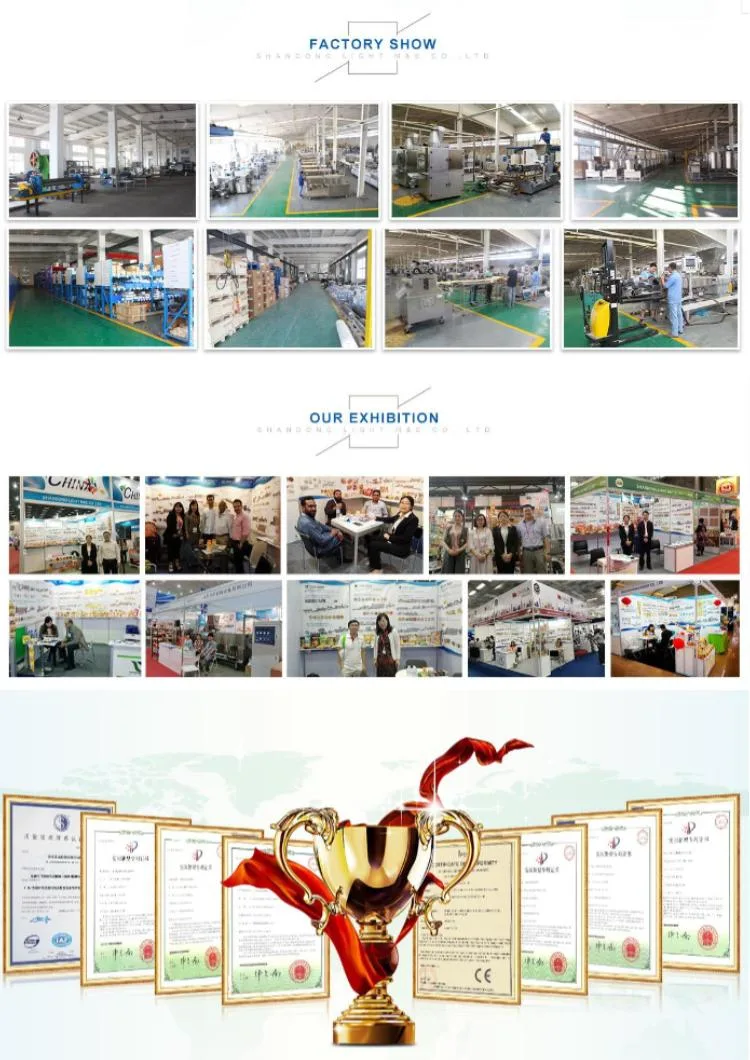

Why Choose Us?

1. Provide production formula, installation, debugging, operator training services. Professional engineers provide machine installation, training, enterprise employees, slove problem, long time machine maintenance.

2. Professional machine maintenance and services. The warranty time of machine and parts is 1 years. Long time maintencance service for spare parts and components.

3. Perfect product quality tracking system after sale, a complete product quality tracking report for each customer, professional analyze, timely feedback.

4. To design and supply non-standard products according to customers' request.

5. For the sake of the global customers, we provide comprehensive consulting service for equipment, technology, raw material, packing, etc. Ensuring customers do not have any worries.

FAQ1. Are you manufacturer or trader?

A: We are professional manufacturer for more than 16 years experience, with professional engineering and after-sales team.

2. What service you supply?

A: We supply 7*24h service Pre-sale, in-sale and after-sale. ODM and OEM service are also available.

3. Do you supply recipe to buyers?

A: Yes, we will supply all recipe and machine parameter setting to customers.

4. If power supply different from yours, can you supply suitable machines?

A: Yes, motor voltage is customized, we will make it according to your requirements. Most commonly are 415V, 50/60HZ; 440V,50/60HZ and 220V, 60HZ.

5.Besides host extrusion line, what other accessories you can supply?

A: We are able to supply full turkey project, including pre-treatment machines and final packing system. It will complete solutionfrom A to Z.

Our Contact