Ate Cheap Double Screw Extruder

Overview ATE Cheap Double Screw Extruder Product Description ATE Series Co-rotating Parallel Twin Screw Extruder pelleti

Description

Basic Info

| Model NO. | ATE |

| Computerized | Computerized |

| Certification | ISO9001:2008, CE |

| Machine Type | Recycling Machine |

| Voltage | 380V 50Hz or Customized |

| Electric Components | ABB, Ls, Omron, or Customized |

| Application | Film, Filament, Raffia, Foam |

| Compacting Room Size | 300-1400 L |

| Capacity Range | 300-1500kg/H |

| Target Being Recycled Material | PP PE Pet ABS PS PC |

| Control | P.L.C Control |

| Sample/Service Manua | Available |

| Factory Location | 2 Hours Drive From Shanghai |

| After-Sale Service | Free Spare Parts |

| Final Product | Pellets/Granules |

| Advantage | Famous Brand Motor |

| Business Type | Manufacturer |

| Material | Iron |

| Transport Package | Wooden Pallet |

| Specification | Customzied |

| Trademark | ACERETECH |

| Origin | Jiangsu Zhangjiagang |

| HS Code | 8477209000 |

| Production Capacity | 100sets/Year |

Product Description

ATE Cheap Double Screw ExtruderProduct Description

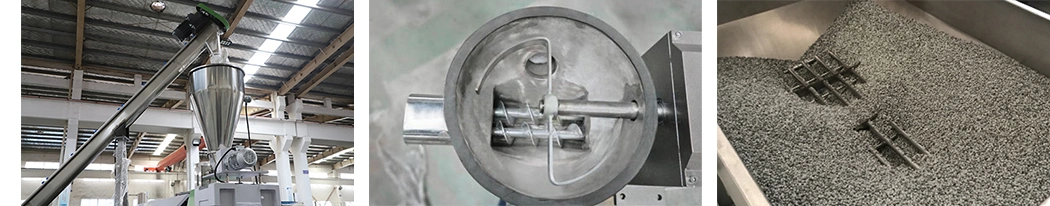

ATE Series Co-rotating Parallel Twin Screw Extruder pelletizing machineACERETECH ATE Series Co-rotating Parallel Twin Screw Extruder pelletizing machine consists of motor drive, torque distribution gearbox, processing section, temperature controlling units, die section and down-stream pelletizing system, etc. Which is a specialized and reliable system.ATE Twin Screw Extruder adopts modular design principle, component standardization manufacturing, which can present stable and reliable performance.Thanks to the modular principle, ATE extruderscan provide highly customizable solutions according to customers' process and special requirements. Based on different output torque grade, ATE series extruders have basic type and efficiency type.

Multiple cutting system can be combined with ATE Twin Screw Extruder, such as strands pelletizing, hot-face cutting and under-water pelletizing, etc.Typical Applications:

1.Fiber reinforcement: glass fiber, carbon fiber reinforced PP,PA,PBT,ABS,AS,PC,POM,PET,PPO,PSF,LCP,etc.2.Ploymer blending :bleding of PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+SBS,etc.3.Incorporation of fillers :CaCO3,Tale,TiO2,carbon black filled PE,PP,or EVA etc.4.Cable Compounds:cable sheath,cable insulation compounds of LDPE,HDPE,LLDPE,MDPE;radiation-crosslinkable compounds,optical fiber protection compounds ,heat-shrinkable polymer compounds.5.Special Compounds :PPR pipe compounds,PE compounds for crosslinked pipes,tobacco filter compounds,etc6.High Concentration Color Masterbatches: PE,ABS,PS,EVA,PET,PP etc. With high concentration of pigments and other procrssing aids.7.Masterbatches with Flame Retardants:PP,PA,ABS,EVA,PBT etc.with flame retardants and other additives.8.Special Functional Masterbatches :Masterbatches with anti-static,anti-abcteria ,or other special functional fillers.9.Masterbatches for Degradable Polymers:PP,PE,PS etc. Blended with high concentration of starch and other processing aids.

Product Parameters

| Machine Size | ATE35 | ATE52 | ATE65 | ATE75 | ATE95 |

| Dia. of screw(mm) | 35.6 | 51.4 | 65.4 | 71 | 93 |

| L/D | 32-64 | 32-64 | 32-64 | 32-64 | 32-64 |

| Screw speed Max(rpm) | 600 | 600 | 600 | 600 | 600 |

| Torque per shaft(Nm) | 115 | 415 | 675 | 990 | 2365 |

| Specific torqueT/A3 | 4.2 | 5.2 | 4.8 | 4.6 | 5 |

| Output(kg/h) | 40-80 | 150-250 | 200-400 | 300-700 | 550-1500 |

Detailed Photos

Company Profile

FAQ

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME

* ACERETECH is original manufacturer.

* If you interested in our products and we can fulfill your request , you may pay a visit to ACERETECH Factory.

* The meaning of visiting supplier, since seeing is believing, ACERETECH Machinery with own manufacture and developed& research team, we can send you engineers and make sure the high efficiency after-sales service.

Prev: Automatic Continuous Belt Crispy Chip Slicing Conveyor Fryer Potato Chip Fryer

Next: 250-300kg/H Puff Snacks Making Machine Processing Line

Our Contact

Send now